The production process of coil springs/

Spring Manufacturing Process and Technologies

How spring are made?

There are various manufacturing processes for springs, including coiling, cutting, heat treatment, spring grinding, correction, surface treatment, assembly, etc. But are not limited to the above.The following spring manufacturing processes will be described using some of our YUUSPRING’S as examples.

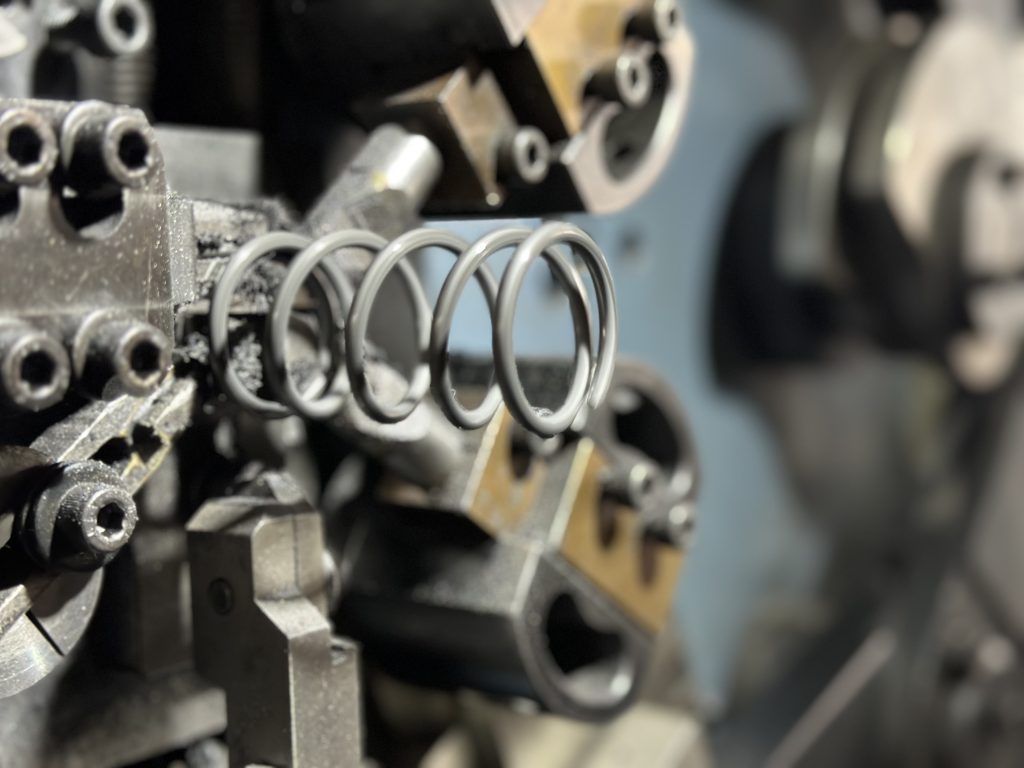

Forming the basic shape of a spring by bending and wrapping metal wire or strip according to specific specifications and requirements.

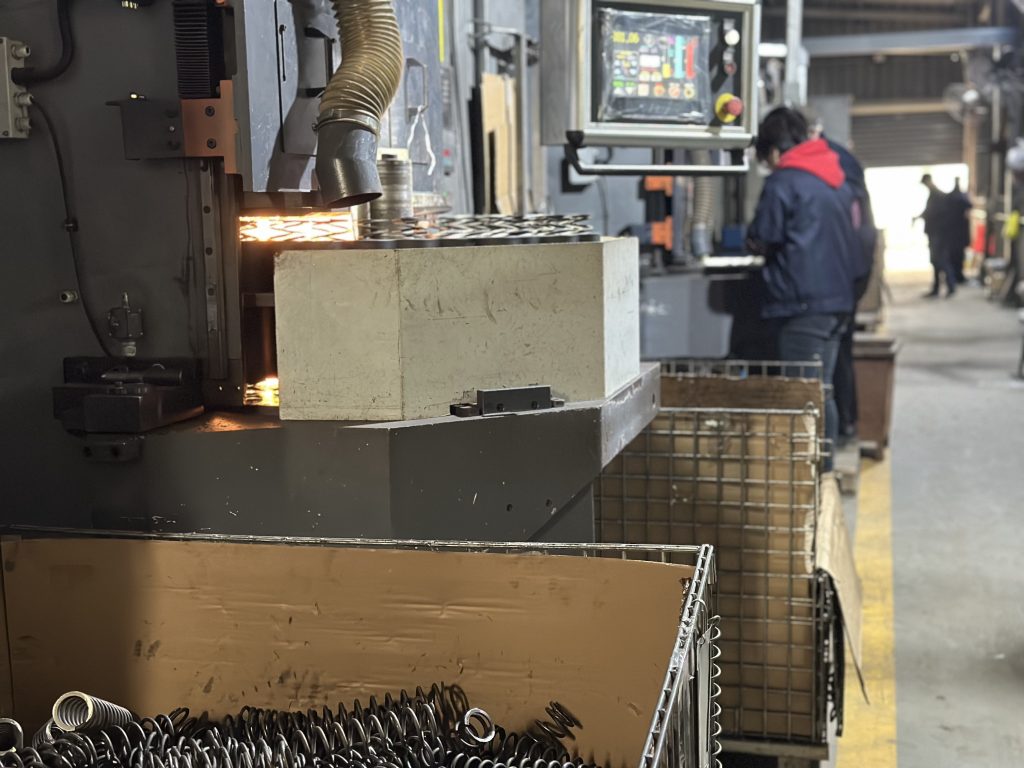

Heat Treatment

Placing preliminarily processed springs into a furnace, heating them at a certain temperature for a period, followed by suitable cooling to alter the material’s physical properties and strength.

Two-end grinding

Precise grinding ensures evenness, enhancing spring connectivity and stability.

Forming

Bending, pressing, or winding previously processed metal wires or strips through mechanical or thermal processes to achieve the final spring shape.(We ususlly use “Spring fixed dynamic pressed” this method.)

Rectification shaping

Accurately adjusting spring shape to meet specifications.

Surface Treatment

Treating the spring’s surface through methods such as galvanization, spraying, or electroplating to enhance corrosion resistance and surface hardness.

Assembly

Bringing together different components to create a complete spring structure, which may involve connectors, end treatments, and related steps.

We often combine and select these manufacturing processes based on specific design requirements and the intended use of the springs.