The reasons for frequent failure of valve springs

What are the main materials of valve springs?

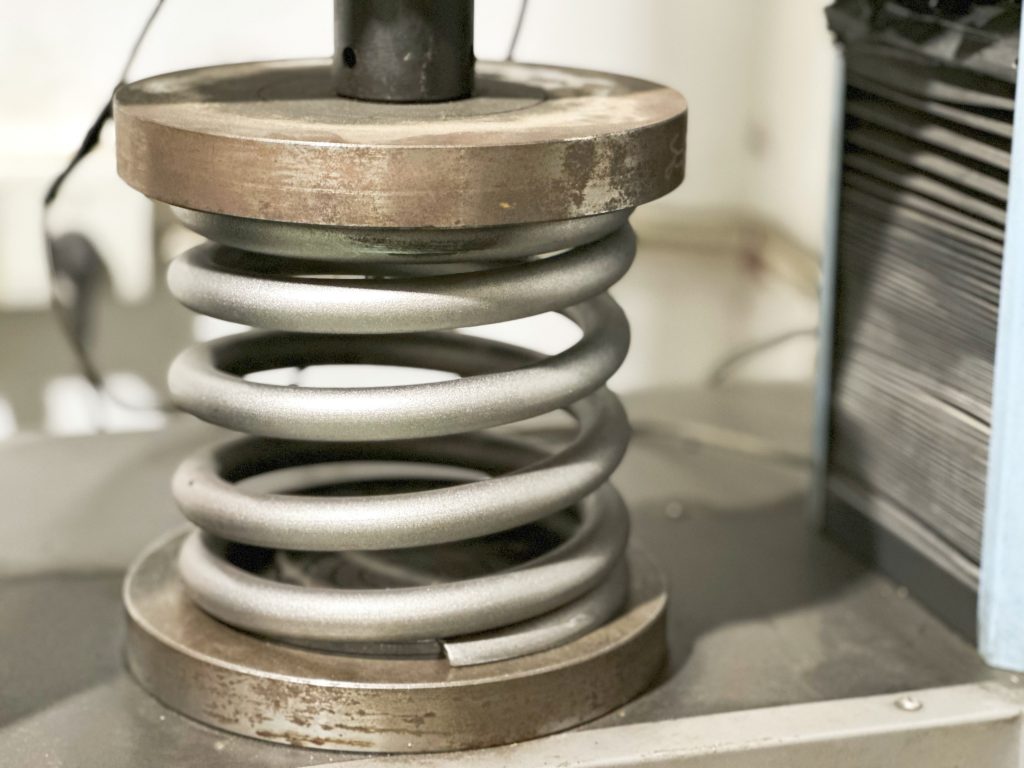

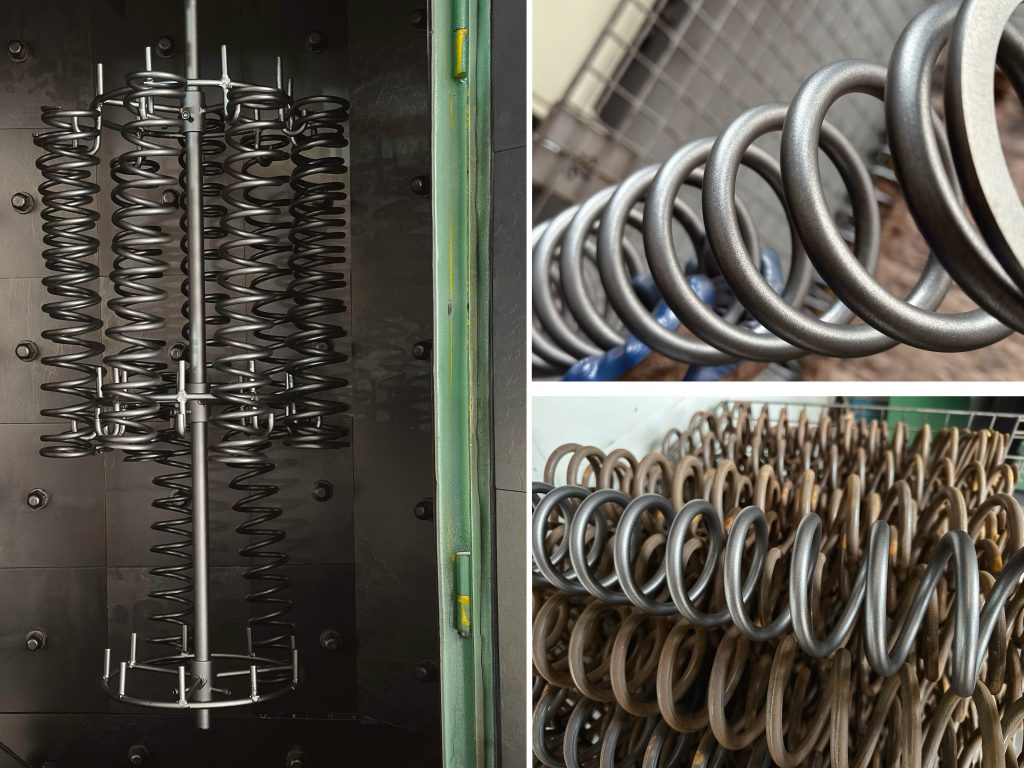

Valve spring: The spring in the valve determines the normal operation of many check valves, safety valves, safety valves and other various valves. The spring determines the opening pressure, the stroke of the valve disc and the stability of the seal in the closed state. Select high-quality GB/T24588-2009 stainless steel spring steel wire, high-temperature spring alloy wire, oil quenched and tempered alloy spring steel wire 50CrVA, 55CrSiA, 60Si2MnA, piano wire, etc. to strictly ensure the spring’s good high temperature resistance, lifespan, stability, and corrosion resistance. performance requirements.

What should you pay attention to when using valve springs?

The valve spring determines the opening pressure, valve disc stroke and sealing stability in the closed state. If there is a problem with these springs, it will be difficult for the entire valve to operate normally. Then we will summarize the reasons for valve spring failure , so that we can pay attention to and avoid them in future operations.

The reasons for frequent failure of valve springs as follows:

1.High pressure

The load borne by the spring can be divided into static load, impact load and vibration load. (According to the form of external force). Most spring failures are caused by large deformation and high stress caused by high load. High stress is only suitable for static load springs, while low stress has a longer fatigue life.

2.Hydrogen embrittlement

Properly hydrogen embrittlement after electroplating or pickling, otherwise the spring steel will become brittle and fail. However, non-ferrous metal valve springs are not affected by this. In the electroplating solution, used for the electrolysis of water molecules, there is always a more or less certain number of hydrogen ions. Some of the hydrogen ions form hydrogen gas and overflow, and some of them penetrate into the coating and the metal body in the form of hydrogen atoms, making the metal body and The toughness of the coating decreases and becomes brittle, which is hydrogen embrittlement. Therefore, dehydrogenating in an oven or resistance furnace after electroplating or pickling. Determining the temperature and time by the size of the spring and the thickness of the coating.Generally, the normal temperature should be between 150-250 degrees Celsius, and the holding time should be between 0.5-5 hours. between.

3.Severe bends and notches

Stretching, twisting and sharp bends caused by flat springs. Notches or scratches in flat springs can cause high stress concentrations and cause failure. Therefore, the bending radius should be as large as possible and avoid printing marks.

4.Fatigue

Repeated deformation of springs, even under moderate stress, may cause fatigue damage. Using low stress when operating conditions are severe. Improving the fatigue resistance of the spring . With reasonable material selection. Shot peening not only gives the spring a smooth surface, but also improves the fatigue resistance of the spring. Extending the service life of the spring, and can alleviate or even prevent surface decarburization, small pits, indentations, cracks and other defects. Shot peening can cause slight plastic degeneration on the surface, and generating the residual stress. It can partially offset the tensile stress generated by the spring when it is repeatedly loaded in the future. The tensile stress is the source of cracks.

Hoping the above summary sharing will be helpful to everyone.