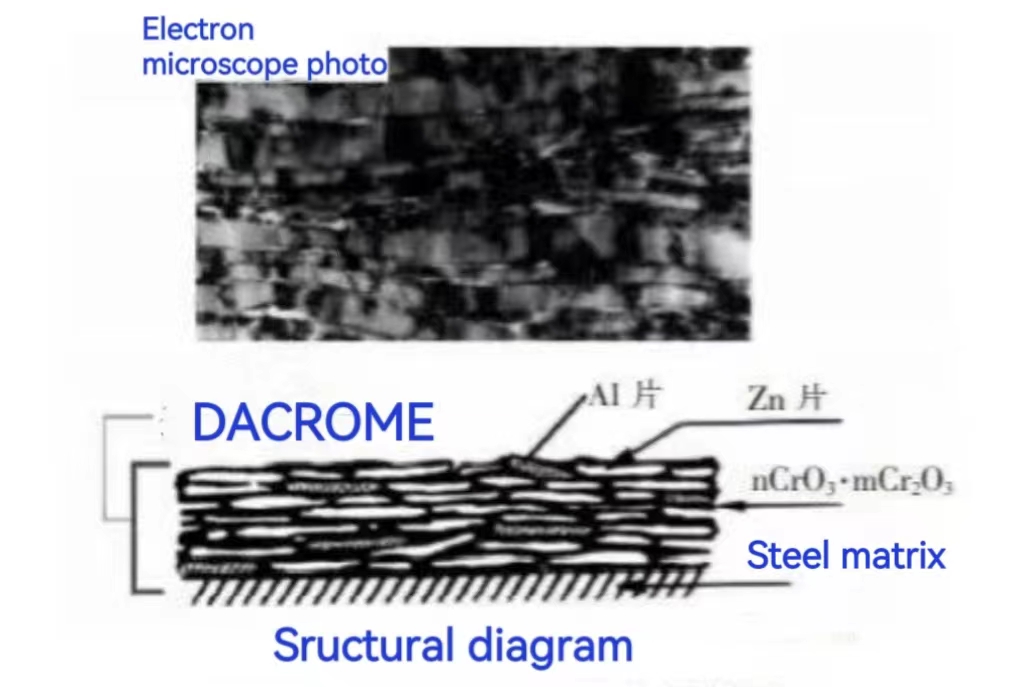

Spring surface treatment DACROMET

The spring surface is generally treated with special treatments to achieve corrosion and oxidation resistance. Such as blackening (blue), phosphating, electroplating, plastic spraying, etc. Then the zinc-chromium film DACROMET appeared. The DACROMET protective layer has excellent corrosion resistance, which is 7-10 times that of the electroplating layer. There is no hydrogen embrittlement caused by the electroplating process, and the electroplating layer has strong corrosion resistance.

DACROMET is an aqueous solution comprising zinc in flake phase, aluminium metal powder and inorganic compound. It is normally treated by dip and spin coating of this aqueous solution followed by heat-treatment at a relatively high. That is, about 300°C temperature. As a result, 7-8 μm thick coating is formed by drying and curing during the hot air drying process. Metal zinc and aluminium, which constitute the coated film, can protect steel via self-sacrificing, namely, by inhibiting the corrosion of a given steel due to the electric activity of highly ionisable metal zinc.

In addition, the zinc, aluminium flake and metal oxide, which are of multi-layered structures can protect the surface of iron alternatively thus functioning as a barrier against external corrosive factors thereby exhibiting superiority in corrosion resistance.

-

Waved Spring

-

Disc Spring

-

Spiral Compression Spring for electric fans

-

Compression spring for warm air blower

-

Control valve diaphragm cover / Diaphragms plate

-

Surface treatment DACROMET Spring

-

TOWER SPRING transmission trans top cover spring

-

Steel wire Thread sleeve Thread Repair Insert Kit Set Stainless Steel For Hardware Repair Tools

-

Disc Spring Material X-750