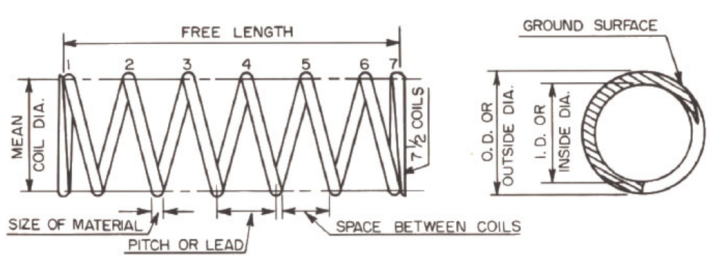

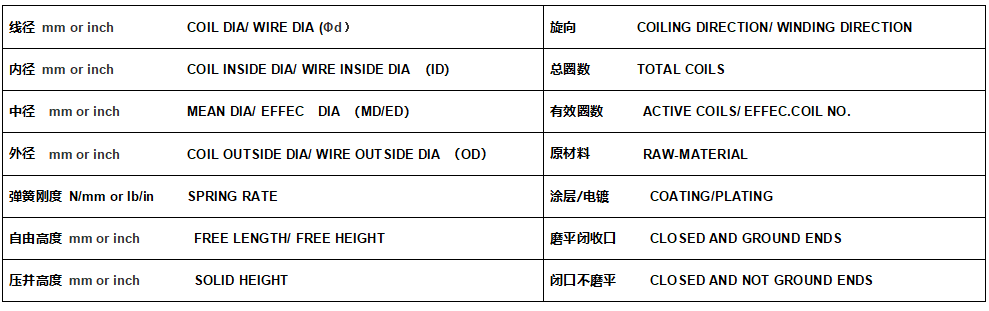

Common symbols and units for springs

*1 inch=25.4mm *1 Ib/in≈0.175N/mm

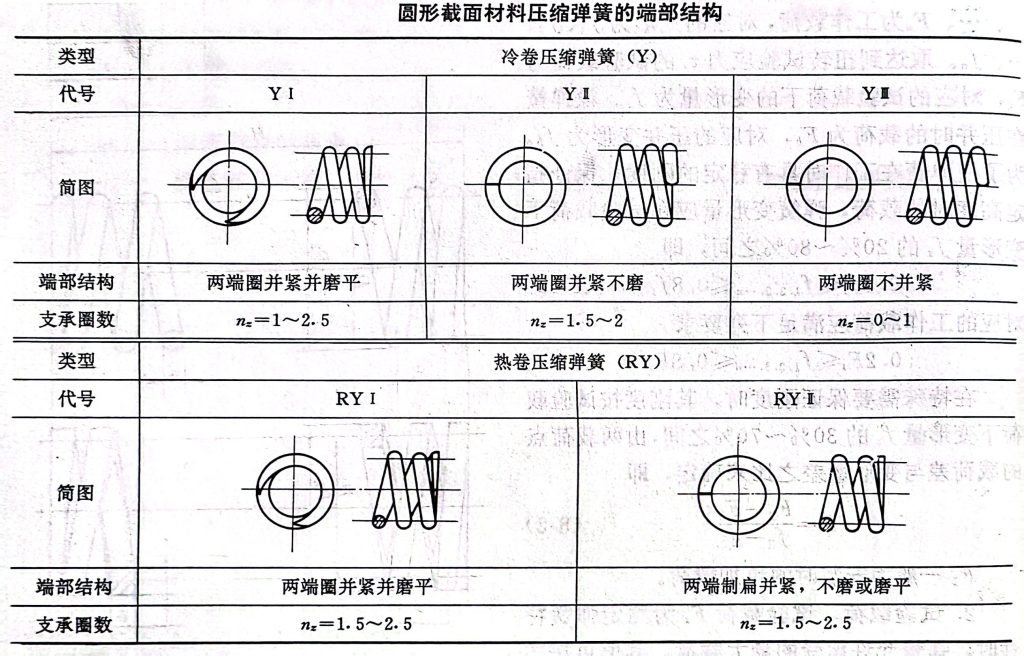

End structure of circular cross-section material compression spring

About Spring rate (https://www.bedfordspeedway.com/toolbox_coils.htm)

Spring rate :The amount of weight needed to compress a spring an inch .(1 Ib/in≈0.175N/mm)To understand and properly check a spring for rate you need to know the factors that determine the rate of the spring. Fortunately, there are only three things that affect spring rate, so there’s not that much to remember!

1.Wire diameter. This affects rate since greater diameter wire is stronger than lesser diameter wire. So, when wire diameter is increased, spring rate increases.

2.Mean diameter of spring. Mean diameter is the overall outside diameter of the spring less one wire diameter. When mean diameter increases, the spring rate decreases.

3.Active coils. Determination of the number of active coils varies according to spring design. Count the total coils minus two for springs with both ends closed (includes all AFCOILS). Count the total coils minus one for springs with one end closed and one end open. As the number of active coils increases, the spring rate decreases.