Spring design, material selection, shape design, fatigue life, stability, surface treatment, safety, compliance with regulations

Spring design is a complex and critical process involving multiple factors, including material selection, shape design, and working environment. The following are the fundamental principles of spring design:

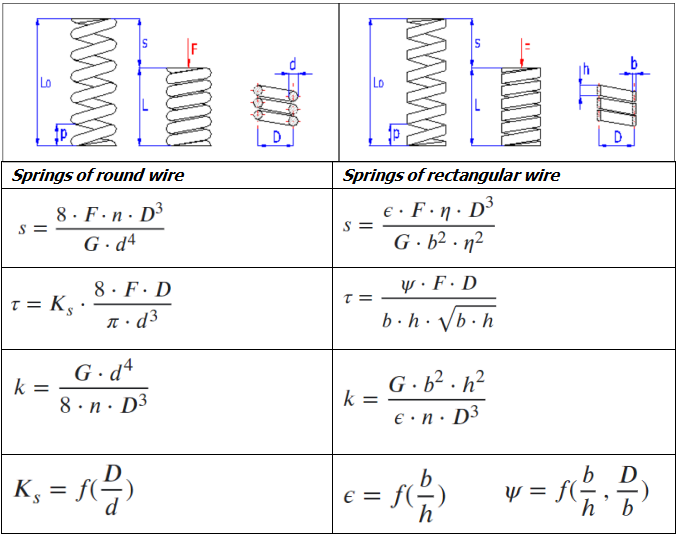

Load and Deformation Relationship

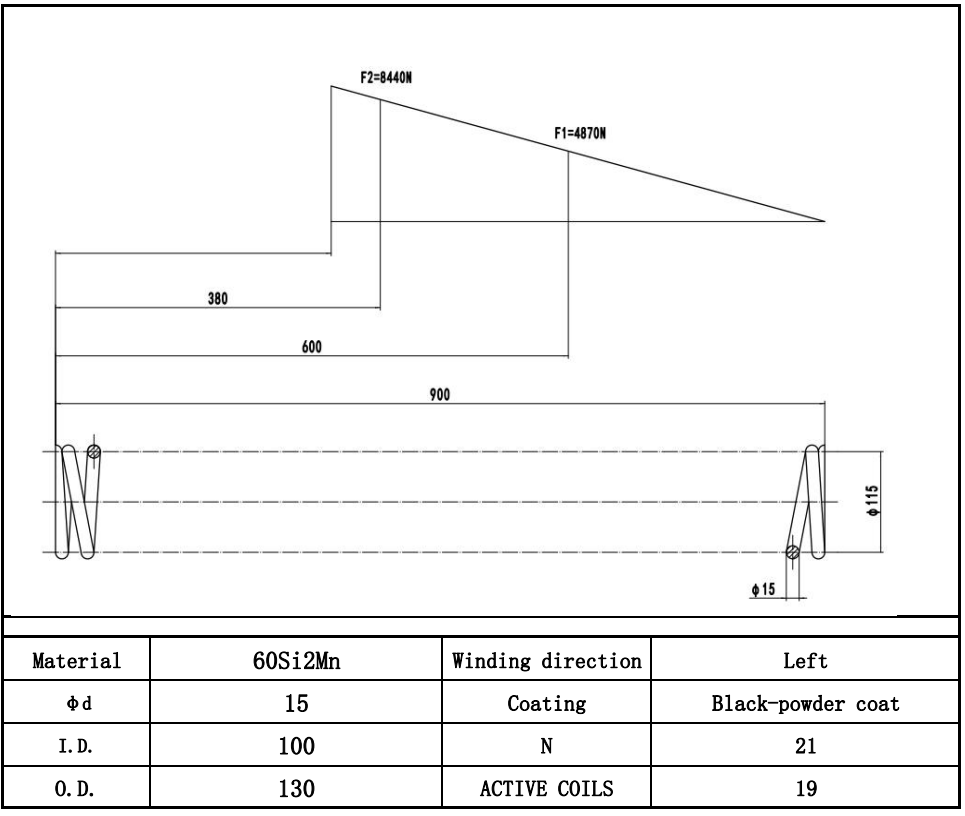

Determine the load that the spring needs to bear and the expected deformation. Choose suitable spring materials and diameters based on the load requirements.

Material Selection

Select appropriate spring materials considering their elastic modulus, fatigue life, and corrosion resistance. Common materials include high carbon steel, stainless steel, alloys, among others.

Shape and Dimensional Design

Ensure that the shape and dimensions of the spring meet the working requirements. Consider parameters such as diameter, pitch, number of coils, etc., to ensure reliable operation within the design range.

Consideration of Fatigue Life

Analyze the anticipated number of working cycles and select the appropriate spring design to meet the life expectancy. Use the fatigue characteristics of the material to predict the lifespan.

Stability and Preloading

Consider the stability of the spring under load to avoid unexpected lateral deflection. Evaluate the necessity of preloading to reduce spring relaxation.

Surface Treatment and Coating

Choose suitable surface treatments or coatings to enhance the spring’s corrosion resistance and surface hardness. Consider environmental factors that may impact the spring.

Safety and Compliance with Standards

Adhere to relevant safety standards and specifications to ensure the design complies with industry and application standards. Consider the spring’s safety under extreme conditions.

These fundamental principles form a solid foundation for spring design, ensuring its reliable operation in various working environments.