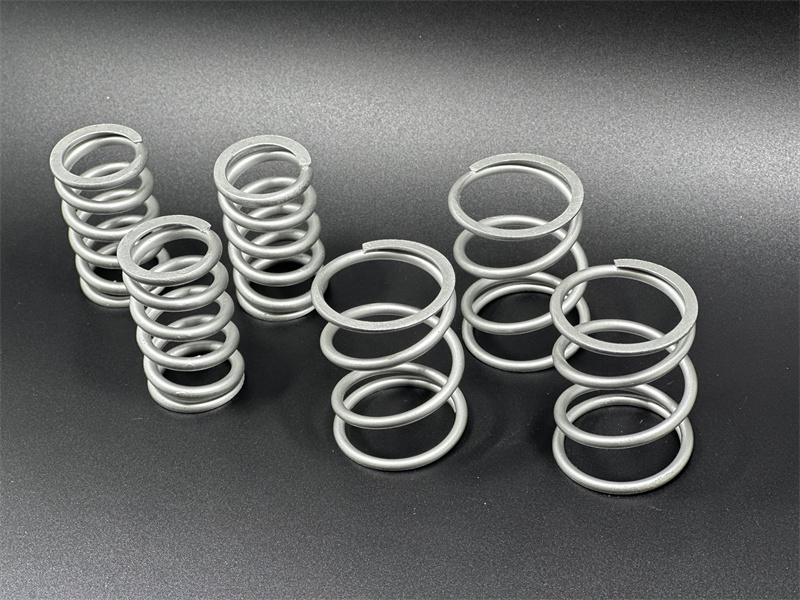

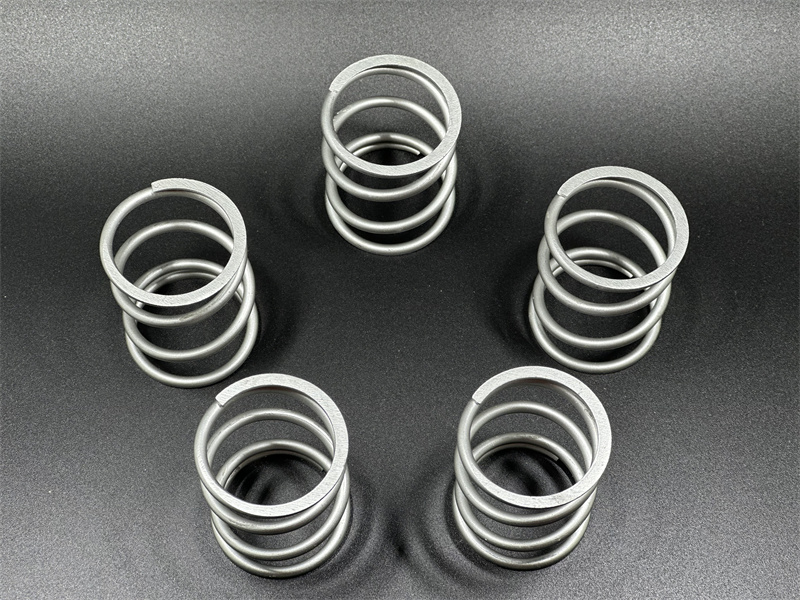

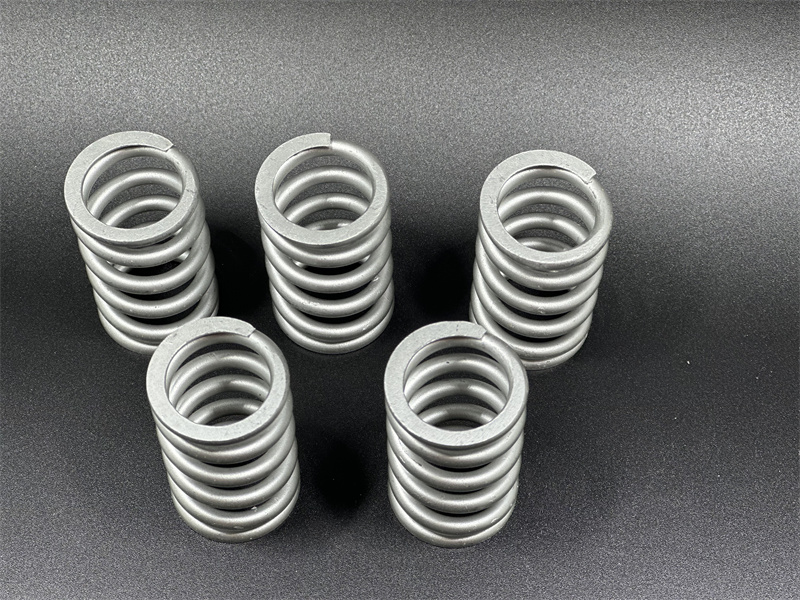

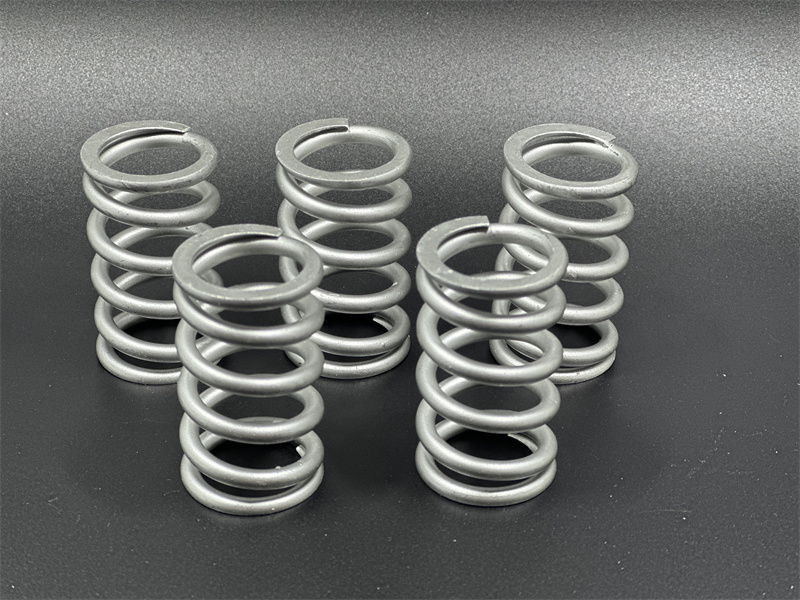

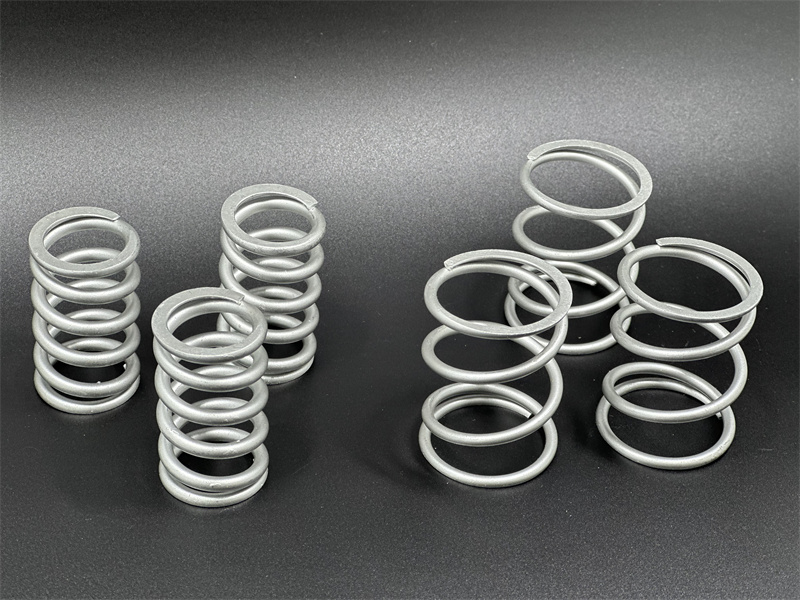

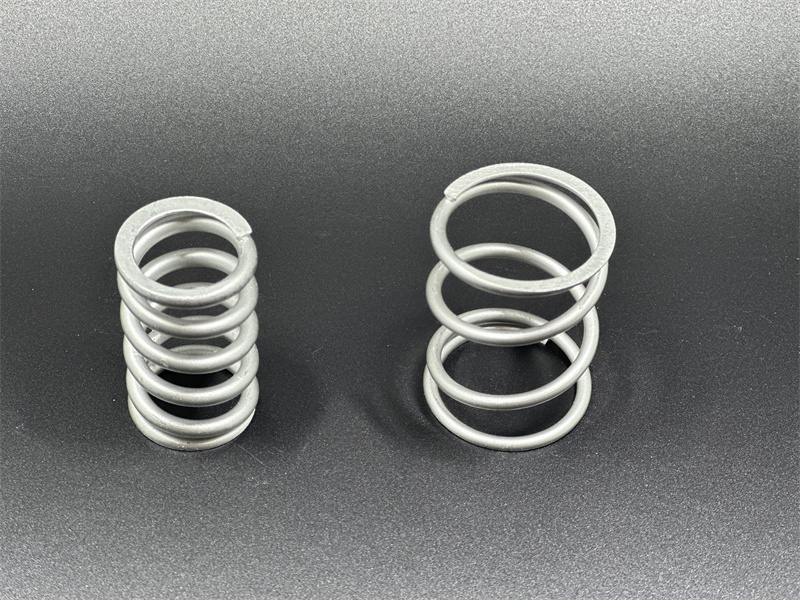

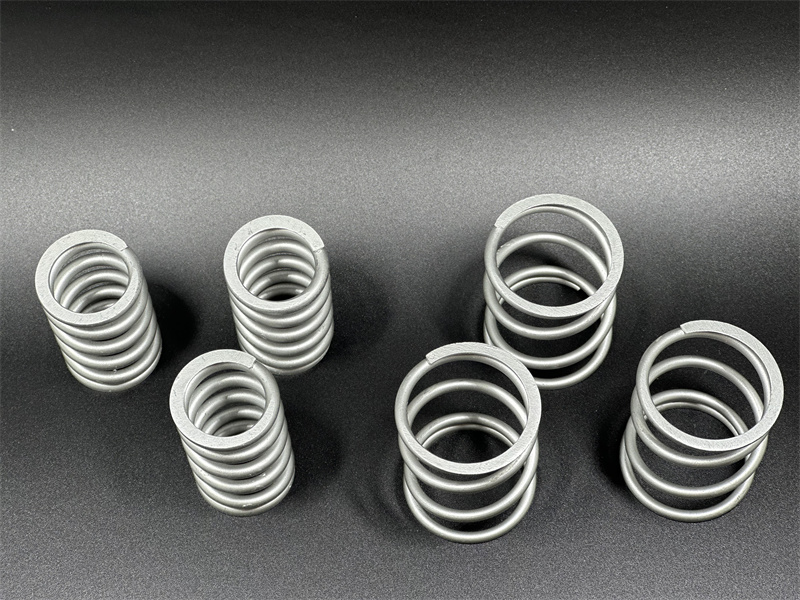

Introducing our cutting-edge product: the Surface treatment DACROMET Spring. Engineered to exceed industry standards, our DACROMET-coated springs offer unparalleled durability and corrosion resistance, making them ideal for a wide range of applications in demanding environments.

Crafted with precision and expertise, our springs undergo a meticulous surface treatment process utilizing DACROMET technology. This advanced coating method involves a zinc-rich primer followed by a topcoat containing aluminum flakes in a special binder. The result is a robust barrier that shields the spring from corrosion, even in the harshest conditions such as exposure to salt spray, chemicals, and extreme temperatures.

The DACROMET coating not only enhances the longevity of the spring but also maintains its mechanical properties, ensuring consistent performance over time. With superior wear resistance and friction reduction, our DACROMET-coated springs exhibit excellent fatigue strength and reliability, making them essential components in critical applications where failure is not an option.

Moreover, our commitment to quality extends beyond the coating process. Each spring undergoes rigorous testing and inspection to guarantee adherence to stringent specifications and standards. From material selection to final assembly, we prioritize excellence at every stage of production, ensuring that our DACROMET-coated springs meet the highest quality and performance benchmarks.

Whether it’s automotive, aerospace, marine, or industrial applications, our Surface treatment DACROMET Springs deliver unmatched performance and longevity, providing peace of mind to engineers and manufacturers worldwide. Invest in reliability, invest in excellence – choose our DACROMET-coated springs for your next project and experience the difference in quality and durability.

Reviews

There are no reviews yet.