1. Classification Methods

Springs can be classified in various ways. Common methods include categorization based on their shape, purpose, materials, and load-bearing characteristics. When selecting a type of spring, it is essential to consider the specific application requirements.

2. Types of Springs Under Different Classification Methods

Classified by Shape

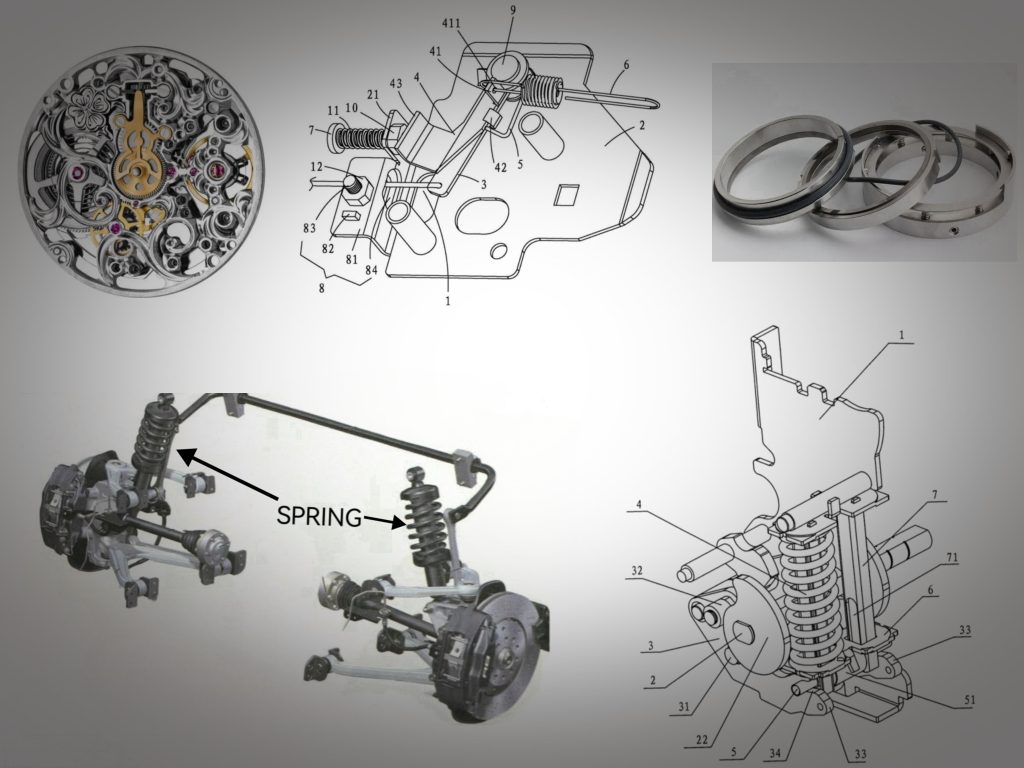

①Coil Springs(Helical Coil Spring/Coiled Spring): Common type of spring characterized by its spiral shape and is typically made from metal wire or strip. Spiral springs come in various types, including compression springs, tension springs, and torsion springs, depending on their specific mode of operation. They find wide-ranging applications in fields such as mechanical, industrial, automotive, electronic, and more, providing elastic support, energy storage, or control of motion.

②Wave springs: They feature a wave-like design, comprising a series of overlapping wave-shaped coils.This design allows wave springs to provide elastic support or pressure in limited spaces.They are used to control and adjust clearances or pressure between mechanical components.Wave springs are typically used in lightweight, compact, and high-precision applications.Common applications include automotive, electronic devices, and instruments.

③Disc springs: Also known as spring washers, are typically circular and made of thin, elastic metal.They provide high elastic force when compressed. Using for shock absorption, maintaining preload, or generating pressure. Also using in applications requiring high elasticity and control. These include engineering machinery, aircraft landing gear, valves, and clutches.

④Oval springs :Have an elliptical cross-section and using for even load distribution.They find applications in some suspension systems and transmission devices.Oval springs can also serve as artistic spring designs.

⑤Custom-shaped(Special-shaped) springs are springs manufactured based on specific needs and design requirements.Their shape and structure can be customized for specific applications.These springs typically do not belong to standard spring types.They are produced according to customer’s precise specifications, dimensions, and functional requirements.

Classified by Purpose

Suspension Spring/ Control Spring/ Energy Storage Spring/ Spring Seal/ Watch Spring

Classified by Material

① Metal material springs: stainless steel, spring steel (50CRVA, 60Si2MnA, 65Mn, 55CrSi, SWP-B)

② Non metallic material springs

Classified by Load-Bearing Characteristics

Compression Springs/ Tension Springs/ Torsion Springs

3. Impact on life

Springs have a wide range of types and play a crucial role in various fields of application. They have improved efficiency, convenience, and safety in both life and industrial fields. They are indispensable mechanical components in real life . And have had a positive impact on the development of society and the improvement of life.