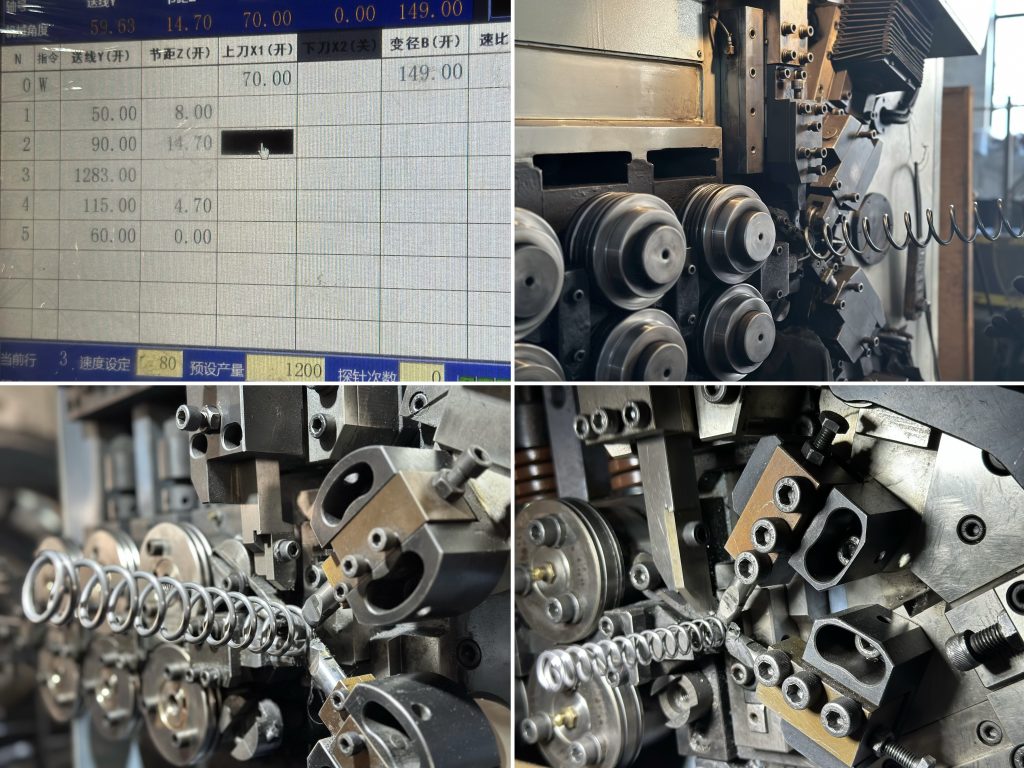

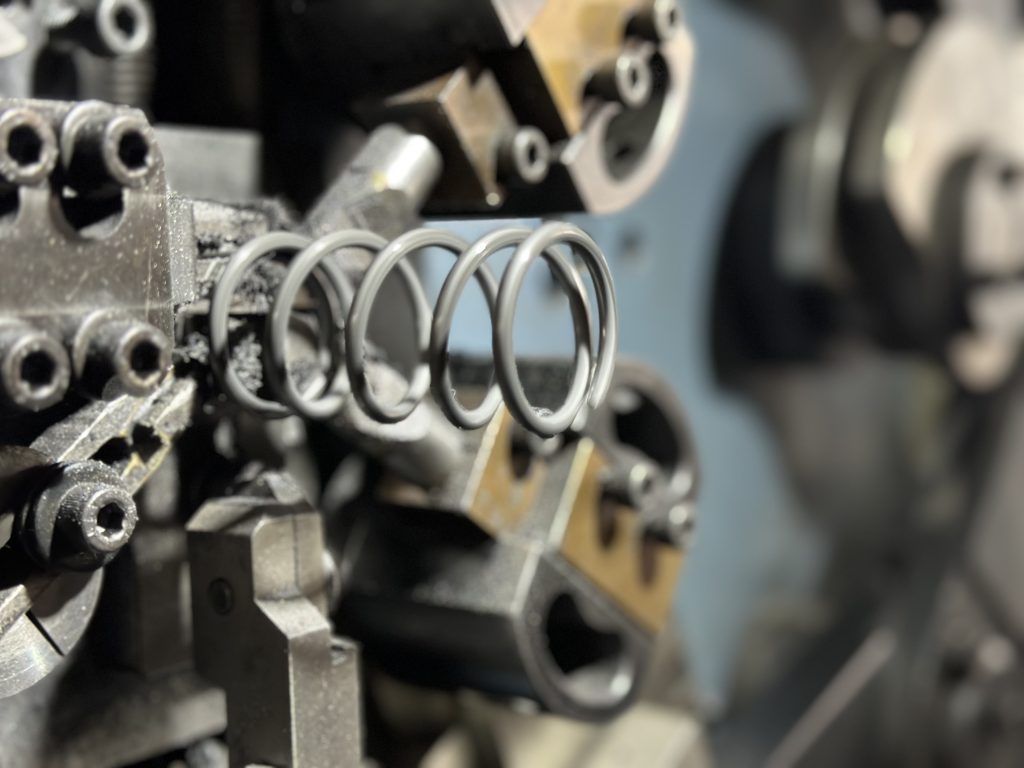

Basic principles of spring design

Spring design, material selection, shape design, fatigue life, stability, surface treatment, safety, compliance with regulations Spring design is a complex and critical process involving multiple factors, including material selection, shape design, and working environment. The following are the fundamental principles of spring design: Load and Deformation Relationship Determine the load that the spring needs to …