Spring Application in Pneumatic Actuator

Mechanism Classification: Pneumatic actuator mechanisms can be classified based on structural forms and pneumatic state requirements.

Classification by Structural Forms:

Diaphragm Type/ Piston Type/ Scotch Yoke / Gear -Rack Type

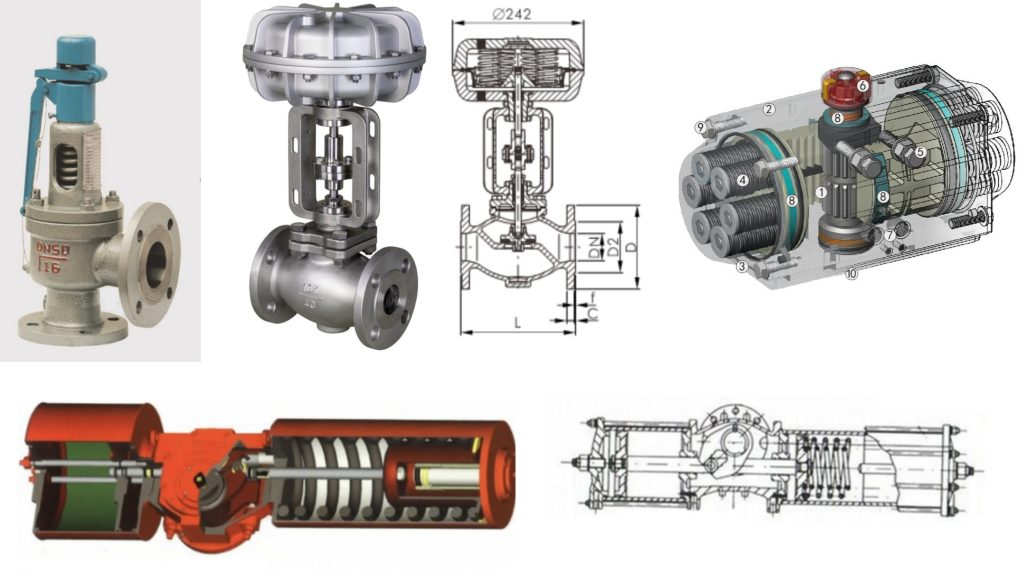

Diaphragm Type , also known as membrane-type, using for valve regulation. They require lower air supply pressure and exhibit good control performance. (Linear stroke)

Piston actuators generate thrust by moving the piston within the cylinder. The output force of piston actuators is significantly higher than diaphragm types. They are suitable for applications requiring high output force, such as large diameter valves or actuation of butterfly valves.

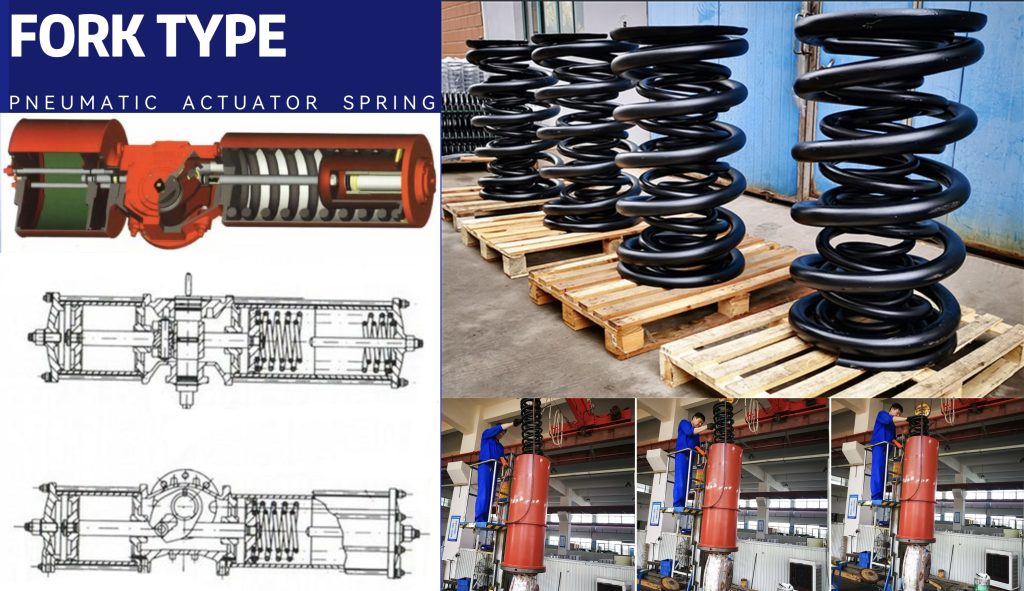

Scotch Yoke Type ,cylinder-based and mainly used for ball valves and butterfly valves. They require higher air supply pressure and produce greater output force or torque. (Angular stroke)

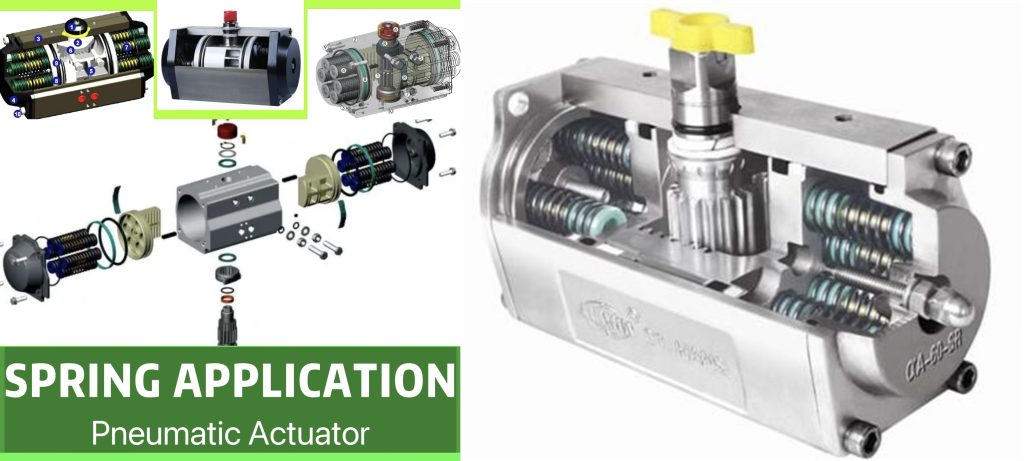

Gear-rack (Dual Piston Gear-rack) pneumatic actuators feature compact structure, elegant appearance, rapid response, stable operation, and long service life. They are utilized in various types of industrial machinery, such as cranes, hoists, and material handling equipment.

Classification by Pneumatic State Requirements:

Single Acting and Double Acting Pneumatic Actuators

Single acting pneumatic actuators with a spring unit. When the air supply is lost, the valve is either fully open (FO) or fully closed (FC). Pneumatic diaphragm actuators are typically of single acting type.

Double acting pneumatic actuators are commonly found in piston-type cylinders. In the event of air supply loss, the valve remains in a neutral position (FL).